A flawless paint texture starts long before the brush hits the wall — it begins with the right foam inside your roller. Here’s how texture paint roller foam works and why the right polyurethane supplier can make all the difference in your finish

When you want a clean, repeatable textured finish on walls or ceilings, the tool that matters most is the texture paint roller foam at the roller’s core. The right foam controls how much paint is absorbed, how evenly it is released, and how consistent the texture looks across each stroke. This is why professional brands and OEMs look for a dependable polyurethane foam supplier that understands how paint behaves on foam.

What is a Texture Paint Roller Foam?

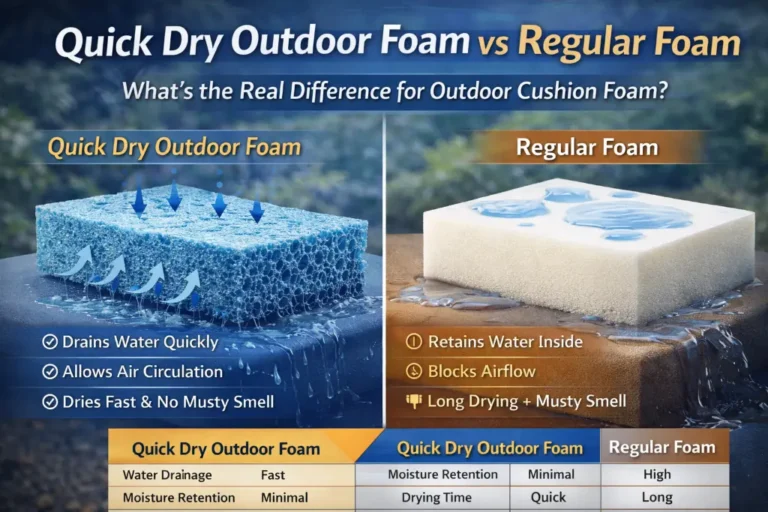

Texture paint roller foam is a precisely engineered paint roller sponge made from reticulated polyurethane. “Reticulated” means the foam has an open, interlinked cell structure. That structure allows the sponge paint roller to load paint quickly, carry it without dripping too much, and release it in a controlled way to create uniform texture.

KareFoam produces roller foams in reticulated polyether PU and reticulated polyester PU. Both are high-performance materials. We recommend the chemistry based on your paint system, desired finish, and durability requirements.

How Does a Sponge Texture Paint Roller Work?

Think of the roller as a miniature pump and metering device.

- Absorption:

Open cells draw paint in through capillary action. Cell size and density determine how fast the foam loads and how much paint it holds.

- Transfer to the wall:

As the sponge roller brush contacts the surface, compression pushes paint out of the cells. The roller releases a controlled film, so you get an even texture rather than blotchy patches.

- Texture build:

The foam’s cell geometry and the roller pattern create peaks, troughs, or stipple effects. Changing PPI (pores per inch), density, and roller surface design lets you move from subtle orange peel to bold designer textures.

- Reload and repeat:

Open cells refill quickly in the tray. The right foam resists tearing and keeps its shape, which reduces roller marks and keeps texture uniform across large areas.

If you want a simple walkthrough of how sponge rollers are used on actual walls, you can refer to how to sponge paint with a sponge roller guide. It shows the practical technique behind creating clean, consistent textures.

Why Use Polyurethane for Texture Rollers?

- Even absorption and release: Open-cell PU delivers smooth, predictable film build.

- Consistent texture: Controlled cell size means repeatable patterns across strokes and batches.

- Low splatter with good flow: Correct PPI balances load with drip control.

- Durability in use: Tear and abrasion resistance help the roller last through multiple jobs.

- Compatibility: Tunable to work with water-based emulsions, acrylics, latex, and many solvent systems.

Key Performance Levers You Can Tune

- PPI (pores per inch): Lower PPI holds more paint and gives a coarser texture. Higher PPI releases thinner films for finer textures.

- Density and hardness: Control how the roller feels on the wall, how it resists compression set, and how it handles aggressive coatings.

- Chemistry:

- Polyether PU is commonly chosen for hydrolysis resistance and broad paint compatibility.

- Polyester PU can be preferred for certain finishes and edge definition.

- Thickness and diameter: Affect loading capacity, stiffness, and ergonomics.

- Cut and finish: Straight cut or profile cut influences the pattern and helps reduce edge marks.

Typical Applications of Texture Paint Roller Foam

- Wall and ceiling texture application in homes, offices, and hospitality spaces

- Decorative effects like stipple, orange peel, suede, stone, and designer finishes

- Industrial coating rollers for machinery and components where a controlled texture is required

- DIY sponge paint rollers that are light, easy to handle, and forgiving for beginners

- Premium painting kits that demand uniform finish and consistent batch-to-batch performance

If your brand sells painting tools, adding a reliable paint roller sponge improves user experience, reduces complaints, and supports repeat sales.

Technical Snapshot (Configurable)

| Foam Type | Reticulated Polyether PU or Reticulated Polyester PU |

| Cell Structure | Open cell, fully reticulated |

| PPI Range | Coarse to fine grades based on desired texture |

| Density Range | Tuned for absorption, release, and durability |

| Thickness / OD | Custom per roller design and handle system |

| Color | Black, white, or custom |

| Compatibility | Water-based emulsions, acrylics, latex, and many solvent systems |

| Formats | Blocks, buns, sheets, or custom-cut roller inserts |

| Packaging | Bulk or unit-packed to OEM spec |

Share your target texture, paint system, and roller geometry. We will match a foam grade for controlled release and a refined surface finish.

Selection Guide for Brands and OEMs

- Define the finish: Subtle or bold texture. This sets your PPI and density window.

- Confirm paint chemistry: Water-based, solvent-based, or specialty coatings. We will align foam chemistry for compatibility and long life.

- Decide loading vs drip control: Higher load is faster but can increase splatter without the right PPI. We balance both.

- Check durability needs: Heavy site use and gritty textures call for higher tear and abrasion resistance.

- Finalize size and ergonomics: Roller length, core diameter, and insert thickness must fit your handle and packaging.

- Validate with trials: Run drawdowns and wall tests to confirm film build, texture uniformity, and clean edges.

Why Leading Brands Choose KareFoam

You need a polyurethane foam supplier that treats foam like an engineered component, not a commodity. KareFoam supports paint roller sponge programs from prototype to scale:

- Application-first engineering: We map foam parameters to your texture, paint system, and user profile.

- Consistent batches: Tight control of density, PPI, thickness, and cut quality for repeatable results.

- Custom sizes and densities: From compact DIY rollers to professional wide rollers.

- Durability built in: Tear and abrasion resistant grades that stand up to real-world use.

- Cost-effective at volume: Smart production and pan-India logistics to hit your lead times.

If you are building a sponge texture paint roller line or refreshing an existing range, we can help you select, test, and lock the right foam grade. KareFoam supplies bulk blocks and custom-cut inserts so your assembly line runs smoothly.

Your B2B Partner for Texture Roller Foam

KareFoam delivers reliable foam solutions for painting tools. Whether you need flexible tuning for a premium kit or a rugged insert for industrial coatings, we can recommend the right polyurethane grade and format. Share your drawings, target texture, and paint chemistry. Our team will send samples and data so you can validate quickly.

Ready to develop your next texture roller?

Talk to KareFoam. A trusted polyurethane foam supplier for brands that want consistent quality, clean textures, and happy end users.

Frequently Asked Questions About Texture Paint Roller Foam

Yes. A sponge paint roller uses reticulated PU to meter paint through open cells for texture creation. Fabric nap rollers are better for flat coats and broad coverage.

Start with a mid-range PPI for a balanced stipple. Move lower PPI for bolder texture and higher PPI for finer finishes.

Often yes, if the foam chemistry is chosen correctly. Tell us your paint system so we can recommend the right grade.

Use the right foam hardness, keep even pressure, and consider profile cuts on the roller ends to soften edges.

Service life depends on paint chemistry, wall prep, and cleaning. With the correct foam and reasonable care, professional users can complete multiple rooms or jobs per roller.