From comfort and cushioning to insulation and filtration, polyurethane foam quietly powers countless products around us. Here’s a simple look at its benefits and why working with the right foam manufacturer makes all the difference.

Polyurethane foam, often called PU foam, shows up in more products than most of us realize. It supports us when we sit, softens the bumps in transit, keeps buildings energy efficient, and even helps air and water pass through cleanly in filters. If you are weighing different foam solutions for your product or project, understanding the core benefits of polyurethane will help you choose with confidence.

What Is PU Polyurethane?

PU polyurethane forms when polyols react with isocyanates and create a cellular structure. By adjusting chemistry and processing, foam manufacturers can create very soft, very firm, or very rigid foams. You will see three broad families in the market:

- Flexible polyurethane foam for cushions, mattresses, packaging, and acoustics.

- Rigid polyurethane foam for panels, appliance cavities, and building insulation.

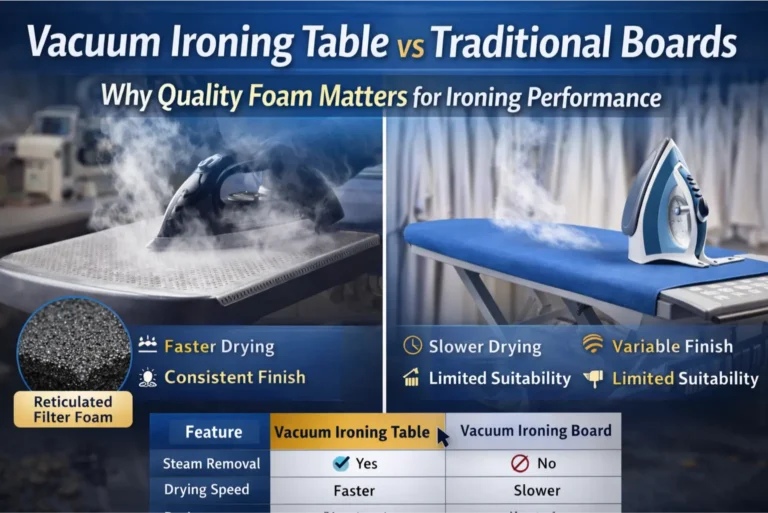

- Reticulated filter foam with highly open, interlinked cells for airflow and filtration.

This range explains why polyurethane products can serve comfort, protection, and performance needs across many industries.

Core Benefits of Polyurethane Foam

1) Comfort and Support You Can Tune

PU foam can be formulated for different levels of softness and firmness. That tunability gives you pressure relief in seating and bedding, while still providing the right support over long use. Designers can choose density and hardness to match the feel they want.

2) Lightweight Strength

For many parts, you want strength without extra weight. PU foam delivers a strong strength-to-weight ratio, which helps reduce shipping costs, improve fuel efficiency in vehicles, and make installation easier at job sites.

3) Excellent Thermal Performance

Rigid PU foam has low thermal conductivity, which makes it an effective insulator in walls, roofs, cold rooms, and appliances. With the right thickness, you can cut heat loss, reduce energy bills, and keep temperatures stable.

4) Reliable Shock and Vibration Absorption

Flexible grades absorb impact and damp vibration well. That is why polyurethane products are common in protective packaging, sports gear, electronics cushioning, and automotive interiors.

5) Real Acoustic Gains

Open-cell structures disrupt sound waves and reduce reverberation. PU foam panels and inserts help improve speech clarity in offices, studios, and vehicles.

6) Filtration and Airflow Control

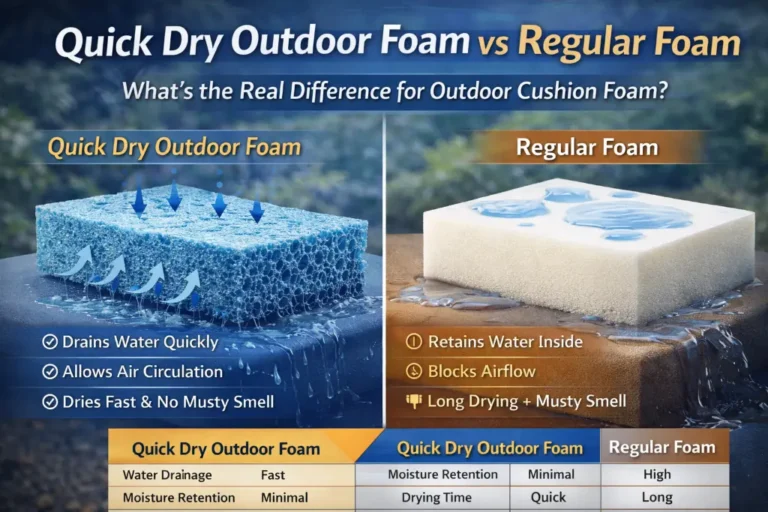

Reticulated filter foam offers high porosity and large surface area. It allows air or water to pass while trapping particles, which is ideal for HVAC pre-filters, compressors, small engines, aquariums, and many industrial filters.

7) Seal, Fill, and Conform

PU foam can be cut, routed, skived, laminated, die-cut, and bonded into many shapes. It conforms to complex geometries and seals gaps, which speeds up assembly and reduces rework.

8) Durability Under Repeated Use

Many PU grades stand up well to repeated compression and recovery. The foam resists permanent deformation when correctly specified for the load and environment.

9) Consistency at Scale

A good polyurethane foam manufacturer can hold tight tolerances for density, cell structure, and thickness. That consistency means fewer defects and smoother production runs.

10) Compliance and Safety Options

Formulations can be engineered to meet fire, smoke, toxicity, and other industry standards. With the right selection, you can match your compliance needs without sacrificing performance.

Where These Benefits Show Up in Real Life

- Furniture and Bedding: Tunable comfort and durability in cushions, sofas, mattresses, and pillows.

- Construction and Insulation: Rigid PU boards and spray systems reduce heat transfer and air leakage.

- Automotive and Mobility: Seats, headliners, door panels, NVH parts, and cabin filters all rely on PU foam.

- Appliances: Fridges and freezers use rigid foams for high thermal resistance.

- Electronics and Packaging: Shock absorption and vibration damping protect sensitive components.

- Filtration: Reticulated filter foam balances flow and capture for HVAC, compressors, and water systems.

- Healthcare: Positioning cushions, supports, and cleanable pads where comfort and hygiene matter.

Polyurethane Foam vs Other Common Materials

| Feature | Polyurethane Foam | Other Common Materials |

| Tunable comfort | Wide range of densities and hardness | Latex or memory foam can feel good but may limit processing options |

| Thermal insulation | Very low thermal conductivity in rigid grades | EPS and XPS are good insulators but offer less conformability |

| Impact protection | Strong cushioning at low weight | Rubber protects well but adds weight and cost |

| Filtration | Open, reticulated cells for stable airflow | Non-woven media filters well but may load faster or restrict flow |

| Converting options | Easy to cut, shape, bond, and laminate | Some plastics are harder to process or bond |

No single material wins every use case. The goal is to match the foam to the job and environment.

How to Choose the Right PU Foam

- Define the goal: comfort, insulation, sealing, or filtration.

- Pick the family: flexible, rigid, or reticulated.

- Set key specs: density, hardness, airflow, or PPI for filters, thermal resistance for insulation.

- Check the environment: heat, humidity, UV exposure, chemicals, and cleaning cycles.

- Plan the format: sheets, rolls, die-cut parts, laminates, or assembled kits.

- Validate with tests: compression set, tensile and tear, airflow, R-value, and aging as needed.

If you want to understand the material families more clearly before selecting, you can refer to this detailed guide on the difference between polyurethane, polyether, and polyester foam. It explains how each type behaves in terms of durability, water resistance, performance, and cost making it easier to match the right foam to your application.

A capable polyurethane foam supplier can guide you through these steps and prototype quickly.

Working With the Right Partner Matters

There are many foam manufacturers in the market, but your results depend on material quality, process control, and converting capability. A dependable polyurethane foam supplier will:

- Map benefits to your use case before quoting.

- Recommend grades that balance performance and cost.

- Hold consistent density and thickness to reduce waste.

- Provide samples and data so your team can validate fast.

- Deliver cut parts or assembled kits to speed up production.

KareFoam: Practical Foam Solutions, Made Simple

If you want the real benefits of polyurethane, start with a clear brief and a partner who can tailor the material. As KareFoam being foam manufacturers, we focus on technical-grade PU across comfort, protection, insulation, and filtration. Our foam solutions include flexible cushioning grades, rigid options for polyurethane insulation, and reticulated filter foam for airflow-critical applications. We can help you choose the right density, hardness, and pore size, then supply sheets, custom-cut parts, laminates, or ready-to-assemble kits at scale.

Need guidance on the best PU foam for your design? Share your drawings, performance targets, and volumes. We will recommend the right polyurethane products and deliver samples so your team can test quickly.

FAQs About the Benefits of Polyurethane Foam

Yes, if you choose the right density and hardness for the load. Properly specified PU cushions maintain comfort and shape over long use.

Rigid PU insulation helps reduce heat loss and air leakage. That translates to better energy efficiency in buildings and appliances.

Reticulated foam keeps airflow stable, tolerates moisture, and can be rinsed or replaced easily. It is a strong option for pre-filters and washable filters.

Yes. Most shops can cut, die-cut, bond, or laminate PU foam to your drawings, which shortens assembly time on the line.