Discover how to choose the right filter foam to enhance your water filtration system’s efficiency and longevity. This guide covers essential factors to consider for effective water treatment and filtration tailored to your specific needs.

When it comes to water filtration, choosing the right material is critical. One of the most effective materials used today is filter foam.

It plays a key role in water treatment and filtration systems across various industries.

Whether you are treating water for industrial use or home applications, understanding the different types of filter foam available can help you make better choices.

Filter foam is a porous, synthetic material used to remove impurities from liquids.

In water filtration systems, this foam traps particles and contaminants. It also supports the growth of beneficial bacteria in biological filtration systems.

Water filter foam comes in various densities, pore sizes, and materials, each suited for specific needs.

What is Filter Foam?

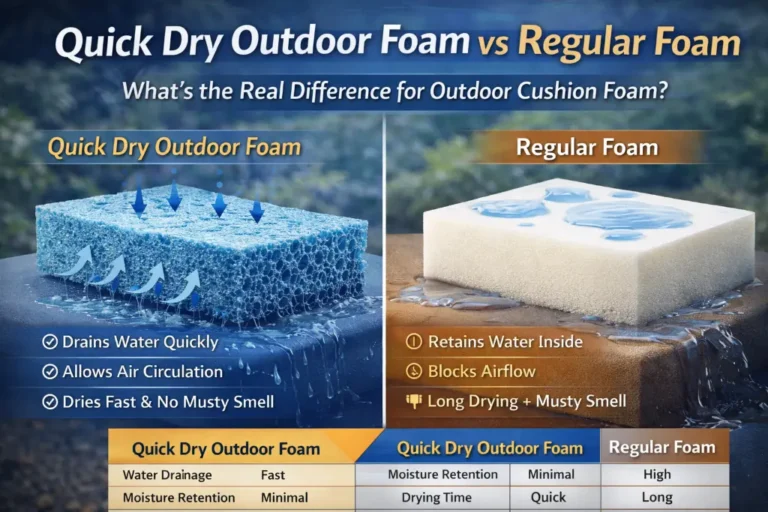

Filter foam is typically made from polyurethane. It is produced in a way that creates a consistent, open-cell structure.

This design allows water to flow through while trapping debris. In water treatment and filtration, the foam must have the right balance of durability, porosity, and flow rate.

The wrong foam can reduce efficiency or fail to remove particles effectively.

Why Use Filter Foam in Water Filtration?

Water filter foam is used because of its flexibility, reusability, and high surface area.

It performs well in both mechanical and biological water filtration systems. It is especially useful in aquariums, ponds, industrial filters, and domestic water filters.

The foam structure helps in removing large particles while also supporting biological filtration.

In water treatment and filtration, maintaining water purity is essential. Foam filters provide an economical solution.

They are lightweight and easy to install or replace. They also offer minimal resistance to water flow while maintaining filtration quality.

Key Factors When Choosing Filter Foam

Choosing the right filter foam involves considering several factors.

These factors impact how effectively the foam performs in water filtration and water treatment, and filtration systems.

Pore Size:

Pore size is a key factor in water filter foam. Larger pores allow higher flow rates, making them suitable for pre-filtration and high-volume applications.

However, they may miss finer particles. Smaller pores offer better filtration by trapping finer contaminants but can reduce flow and require more frequent cleaning or replacement.

Foam Density:

Foam density affects both durability and filtration efficiency. High-density filter foam provides greater surface area, capturing more debris and allowing better biological filtration.

It is ideal for long-term use. Lower-density foam offers higher flow but may degrade faster. Selecting the right density ensures balance between performance, maintenance, and system longevity.

Material Type:

| Feature | Polyether‑Based Foam | Polyester‑Based Foam |

| Moisture Resistance | Excellent – ideal for water filtration and aquatic systems (hydrolysis‑resistant) | Moderate – suitable for dry air systems, less stable in wet environments |

| Durability in Humidity | Highly resistant to hydrolysis and long-term moisture | Prone to degradation and loss of strength in humid/moist settings |

| Best Use Cases | Water filters, aquarium/pond filtration, industrial water systems | Air filters, HVAC systems, dry filtration tasks |

| Chemical Resistance | Very good – handles typical water-borne substances | Good – often used where organic chemicals or aerosols are present |

| Cost | Slightly higher — due to engineering for hydrolysis resistance | Typically lower cost; simpler chemistry |

| Available at Kare Foam | ✔ Offered and recommended for water filtration | ✔ Offered primarily for air-based and dry systems |

Application:

Each application demands a specific foam type. Industrial systems often require fine, durable filter foam that can handle continuous use and higher contamination loads.

Home and aquarium setups benefit from medium-density foam that balances flow and filtration.

The foam design must match the intended purpose for best water treatment and filtration.

Maintenance and Replacement

Even the best water filter foam needs regular maintenance.

Foam should be cleaned regularly to prevent clogging. It can usually be rinsed with clean water and reused several times.

However, over time, the foam will degrade. It is important to replace it when it loses shape or performance.

Applications of Filter Foam

Filter foam plays a vital role in water filtration, offering efficient solutions for various water treatment and filtration applications.

- Home Water Filters:

In home water filtration systems, filter foam removes dirt, sediment, and suspended particles from tap water. It ensures cleaner, safer water for daily use.

Its lightweight and reusable design makes it cost-effective. Foam filters can be cut to fit various filter housings, making them a flexible solution for residential water needs.

- Aquariums and Ponds:

Water filter foam is essential in aquariums and pond systems. It provides both mechanical filtration by capturing debris and biological filtration by supporting beneficial bacteria.

These bacteria help break down harmful waste. The aquarium filter foam open-cell structure ensures steady water flow, helping to maintain a clean and healthy aquatic environment for the long-term.

- Industrial Water Systems:

In industrial applications, filter foam is used to manage high flow rates and remove fine particles.

Systems treating large water volumes benefit from the foam’s durability and efficient contaminant removal.

It also supports continuous operations by reducing clogging. Industries rely on foam filters for reliable water treatment and filtration performance.

- HVAC Systems:

Though not related to water filtration, filter foam is widely used in HVAC systems for air filtration.

It traps dust, pollen, and airborne particles, improving indoor air quality. The foam structure allows maximum airflow while maintaining effective filtration.

Its flexibility and easy maintenance make it suitable for commercial and residential systems.

Each application has different requirements. This makes choosing the right foam even more important.

Final Thoughts

Choosing the right filter foam is not just about pore size or density; it’s about performance, reliability, and long-term results in any water treatment and filtration setup.

At Kare Foam, as we are the best polyurethane foam supplier in India, we focus on delivering consistent quality with our reticulated PU filter foam, engineered specifically for water filtration systems that demand efficiency and durability.

We offer both polyether and polyester-based foams, with customizable specifications to match the exact needs of your application.

Our solutions are tested, trusted, and built to integrate seamlessly into various filtration environments, from home units to industrial systems.

We know filtration. We engineer performance that lasts. Explore our range and get the filter foam that’s made to work just as hard as your system does!