Discover how polyurethane foam shapes our everyday comfort, insulation, and filtration — from the sofas we sit on to the walls that keep our homes warm. Here’s a simple guide to its uses, types, and why choosing the right manufacturer matters.

Polyurethane foam is a versatile material that we see in everyday life. It cushions your sofa, insulates your fridge and roof, filters air and water, and even helps paint rollers lay down a smooth finish. At its core, polyurethane foam forms when two main ingredients, an isocyanate and a polyol, react and create a cellular structure that can be soft and flexible or hard and rigid. That structure is why the same family of foams can work for both a mattress and a wall insulation panel.

Polyurethane Foam Basics

Before we dive into polyurethane foam uses, let’s understand two key ideas:

- Open-cell vs closed-cell:

Open-cell foams let air pass through, so they are great for cushioning, sound absorption, and filtration. Closed-cell foams trap gas inside the cells, so they resist water and heat flow and work well for thermal insulation.

- Flexible vs rigid:

Flexible polyurethane foams are soft, compressible, and spring back. Rigid polyurethane foams are stiff and strong for insulation and structural applications. There is also spray polyurethane foam that is applied on site for roofs and walls.

Types of Polyurethane Foam

When buyers search for “types of polyurethane foam,” this is what they usually mean:

Flexible Polyurethane Foam (FPF)

- Open-cell structure, soft feel, good rebound.

- Used for seating, bedding, packaging, and acoustics.

Rigid Polyurethane Foam (RPF)

- Closed-cell structure, high thermal resistance, low weight.

- Used for boards, panels, appliances, and building envelopes.

Spray Polyurethane Foam (SPF)

- Site-applied foam for roofs and walls that expands to seal gaps.

- Improves energy efficiency and reduces air leakage.

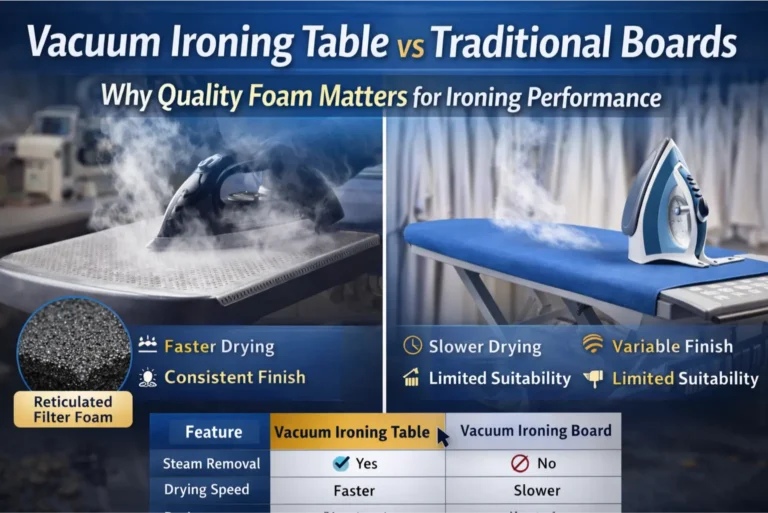

Reticulated Polyurethane Filter Foam

- Highly open, interlinked cells created by a special “reticulation” process.

- Excellent airflow and surface area for air, water, and oil filtration.

Specialty and Modified Grades

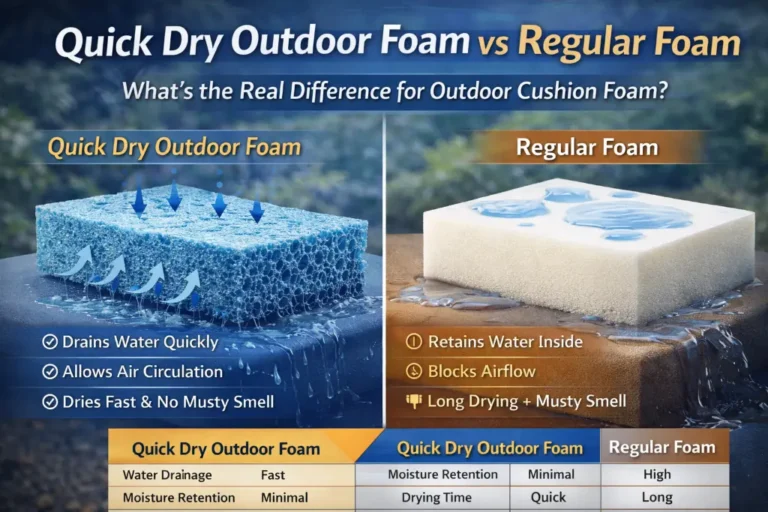

- Quick-dry outdoor foams for cushions and marine use.

- Technical foams tailored for paint rollers, gaskets, and acoustic parts.

Polyurethane Foam Uses by Industry

If you are evaluating polyurethane foam uses, here is a quick sector-wise guide.

1) Furniture and Bedding

- Cushions, mattresses, pillows: Flexible polyurethane foam gives comfort and support. It resists compression set and springs back after use.

2) Building and Construction

- Polyurethane foam insulation in boards or spray form helps reduce heat loss and air leakage. It is lightweight yet rigid, so it adds thermal performance without bulky thickness. Buyers often search for terms like polyurethane insulation or polyurethane foam insulation when they want better energy savings with fewer joints and gaps.

3) Appliances

- Refrigerators and freezers rely on rigid polyurethane foam for high-performance insulation.

4) Automotive and Mobility

- Seats, headrests, acoustic panels, HVAC filters: Flexible foams add comfort and noise control, while filter foams keep air clean.

5) Filtration

- Air and water filters, pre-filters for HVAC, aquarium filters: Reticulated polyurethane filter foam offers high flow with debris capture due to its open, three-dimensional network.

6) Tools and Coatings

- Texture paint rollers use specialty foam grades to hold paint and release it evenly on the wall.

7) Outdoor and Marine

- Quick-dry outdoor cushions use open, reticulated foam that drains water fast and dries quickly. It is ideal for poolside, marine, and patio seating.

Why Work with a Polyurethane Foam Manufacturer Instead of Generic Foam?

Choosing a polyurethane foam manufacturer matters when you need:

- Right pore size and airflow for filters

- Consistent hardness and density for comfort parts

- Tight dimensional control for gaskets and seals

- Application-ready formats like sheets, rolls, cut parts, and assembled kits

A specialist can match foam grade, thickness, density, and porosity to your job so that performance and cost are both optimized.

Buyer’s Guide: How to Choose the Right Polyurethane Foam

Use this simple checklist when shortlisting foam for your project:

Define the job

- Cushioning, insulation, sealing, or filtration?

Pick the foam family

- Flexible for comfort and acoustics.

- Rigid for thermal insulation and structure.

- Reticulated for filtration and fast drainage.

Set the key specs

- Density and hardness for comfort parts.

- Cell openness or PPI for polyurethane filter foam.

- Thermal resistance and closed-cell content for boards and polyurethane insulation.

Check environment and compliance

- Heat, humidity, UV, chemical exposure, and any industry standards that apply.

Confirm formats and converting

- Sheets, rolls, die-cut parts, laminates, and bonded assemblies. Working with a capable polyurethane foam manufacturer helps reduce downstream costs through ready-to-use parts.

Your Partner in Tailored Polyurethane Foam Solutions

If you are exploring polyurethane foam, remember that the right choice starts with the job. Use flexible foams for comfort and acoustics. Choose rigid foams and polyurethane insulation for energy savings. Select reticulated polyurethane filter foam when you need airflow and filtration. KareFoam can help you match the grade, pore size, and format to your application and supply consistent quality at scale.

At KareFoam, we focus on technical-grade polyurethane solutions for industrial, automotive, and comfort applications. Our team offers engineered reticulated filter foams, quick-dry outdoor foams, and application-specific grades for texture paint rollers and more. If you need tailored pore size, airflow, or custom converting, you can explore our product pages to see how they align with your use case.

Need help selecting the right polyurethane foam grade?

Speak to our team at Kare Foam, we guide OEMs, manufacturers, and brands with engineered PU foam solutions.

Common Questions About Polyurethane Foam

Yes, when sourced from reputable suppliers and used as intended. Flexible foam used in furniture and bedding and rigid foam used for polyurethane foam insulation are widely used in homes and appliances. Always follow the product’s handling and ventilation guidance.

Open-cell foam is softer and lets air through, so it helps with sound absorption but does not block moisture well. Closed-cell foam is rigid, resists water, and has higher thermal resistance, so it is preferred for walls, roofs, and cold rooms.

Its highly open structure gives high airflow and lots of surface area to trap debris or support biofiltration in water systems. That balance of flow and capture is why polyurethane filter foam is popular in HVAC pre-filters, aquariums, and industrial air cleaners.

Choose specialty grades. Quick-dry, reticulated foams are designed to drain water and dry faster for outdoor and marine seating.

Texture paint roller foams are engineered for the right porosity and tear resistance so the roller loads and releases paint evenly.