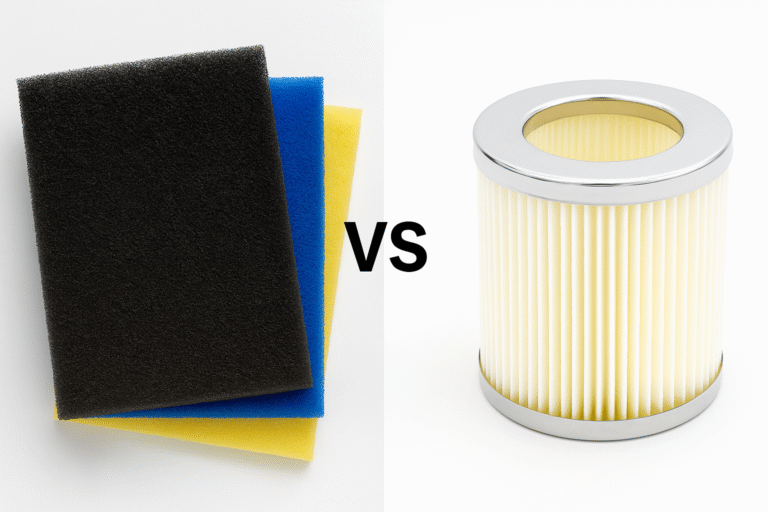

Choosing the right air filter is essential for performance and longevity. Here’s a clear comparison between foam air filters and cotton air filters to help you make an informed choice.

For industrial machinery, HVAC systems, and engines to operate effectively, air filters are essential. They ensure cleaner operation and longer equipment life by removing dust, debris, and other airborne particles. Performance and maintenance can be significantly improved by selecting the appropriate kind of air filter.

Cotton air filters and foam air filters are two of the most widely used materials. Depending on your priorities, each has special advantages and disadvantages. Cotton filters frequently offer superior durability and airflow, while foam filters are renowned for their ability to filter fine particles and their resistance to water.

In this guide, we’ll break down the differences between foam air filters and cotton air filters, highlighting their benefits, drawbacks, and the best applications for each type.

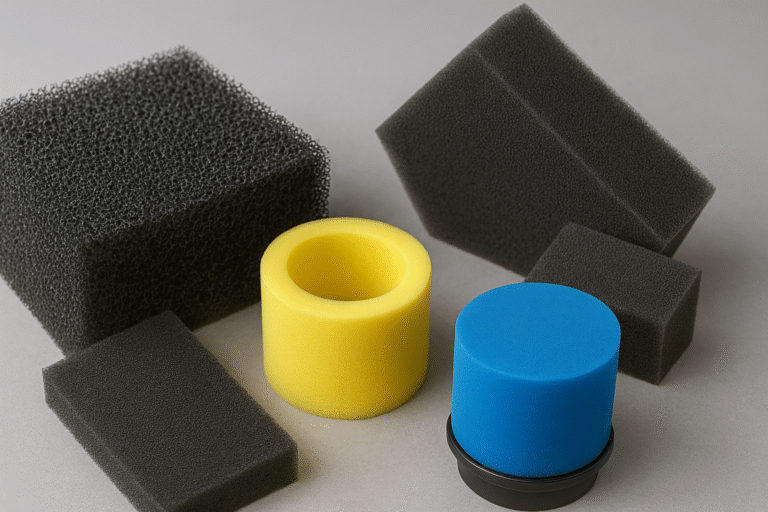

What Are Foam Air Filters?

Foam air filters are made from open-cell filter foam, such as polyurethane or polyester filter foam, designed to trap dust, dirt, and other fine particles while allowing air to pass through.

They are reusable and reasonably priced due to their high filtration efficiency, water resistance, and ease of cleaning. The thick structure of the foam offers superior protection in abrasive or dusty conditions.

The main trade-off is that foam filters can slightly restrict airflow compared to cotton filters, but their ability to capture finer particles often outweighs this for many applications.

What Are Cotton Air Filters?

Cotton air filters are made from woven or multi-layered cotton fibers, sometimes combined with materials like waffle cotton. They are designed to provide high airflow while filtering dust and debris.

Because of their durability, cotton filters typically need to be replaced less frequently under normal circumstances. To maintain optimum performance, they may require more frequent cleaning and be less successful at capturing extremely fine particles. When engine performance and airflow are more important than maximum particle filtration, these filters are frequently chosen.

Side-by-Side Comparison: Foam vs. Cotton

Both foam air filters and cotton air filters have their own advantages and trade-offs. Understanding the differences can help you choose the right filter for your specific needs.

| Feature | Foam Air Filters | Cotton Air Filters |

| Filtration Efficiency | Dense foam structure captures fine dust and contaminants effectively, protecting engines and equipment. | Less dense than foam; better for general dust but slightly less effective with fine particles. |

| Airflow | Slightly restricted due to denser material. | Typically higher airflow, which can improve engine performance and responsiveness. |

| Maintenance | Easy to clean and reusable, making them cost-effective over time. | Requires more frequent cleaning for optimal efficiency; can clog faster in dusty environments. |

| Durability | Good durability, though repeated cleaning may reduce lifespan over time. | Generally more durable under normal conditions and less prone to tearing. |

| Water Resistance | Naturally water-resistant, ideal for wet or humid conditions. | Less resistant to moisture; prolonged exposure can affect performance. |

In short, foam filters are ideal for environments where filtration efficiency and particle capture are critical, while cotton filters are better when airflow and durability are the main priorities. Your choice depends on whether you value cleaner air, easier maintenance, or better airflow.

Applications and Best Use Cases

Both foam air filters and cotton air filters are widely used across vehicles, HVAC systems, and industrial equipment, but their suitability varies based on the application:

- Foam Air Filters

- Ideal for harsh or dusty environments, such as off-road vehicles or industrial machinery.

- Excellent for fine particle filtration in engines, HVAC units, and medical devices.

- Reusable and washable, making them cost-effective for frequent maintenance cycles.

- Cotton Air Filters

- Best suited for applications where airflow is a priority, like performance vehicles or equipment requiring high ventilation.

- Durable under normal operating conditions, providing long-lasting service with proper cleaning.

- Works well in less extreme environments where moisture and fine dust are not a major concern.

By understanding the strengths of each, you can select the right air filter type to balance efficiency, airflow, and maintenance for your specific needs.

Why High-Quality Foam Makes a Difference

The quality of the filter foam used has a significant impact on how well foam air filters work. Low-quality foam can reduce filter life and overall performance by tearing easily, losing its shape, or ineffectively capturing fine particles.

Durability, steady airflow, and efficient filtration are provided by premium polyester or polyurethane filter foam. Because it is reusable, washable, and impervious to heat, moisture, and chemicals, it can be used in a variety of settings, including industrial equipment, automobiles, and HVAC systems. Learn more about the difference between polyurethane, polyether, and polyester foam to understand which type best suits your filter needs.

Choosing the Right Filter for Cleaner Air

The most important factors, such as durability, airflow, or filtration efficiency, will determine whether to use cotton or foam air filters. Cotton filters are best suited for applications needing greater airflow and long-term durability, while foam filters are excellent at handling difficult conditions and capturing fine particles.

Kare Foam offers premium air filter foam and filter foam sheets that are customized to meet your unique requirements. Our polyester and polyurethane foams are made to last, perform reliably, and require little upkeep. With our ISO-certified production, decades of experience, and adaptable solutions, we assist companies and manufacturers in making sure their filters provide optimal performance.

Explore our range of foam air filters and custom solutions today, and experience the difference that quality filter foam can make. Contact Kare Foam for expert guidance and reliable supply.