Discover how filter foam keeps air clean, the types used in air filters, and why choosing the right foam matters for performance and durability.

Clean air matters — in your car, home, workplace, or even in medical devices. And one of the unsung heroes behind clean air is filter foam. This special foam is designed to trap dust, debris, and other particles while still letting air pass through easily.

Different types of foam are used depending on where the filter will be placed and the kind of conditions it faces. For example, polyester filter foam offers strength and chemical resistance, while polyether foam handles humid or wet environments with ease. Choosing the right foam not only improves air quality but also helps your filters last longer and perform more efficiently.

In this article, we’ll break down what filter foam is, the main types used in air filters, their features, and common applications across industries.

What Is Filter Foam?

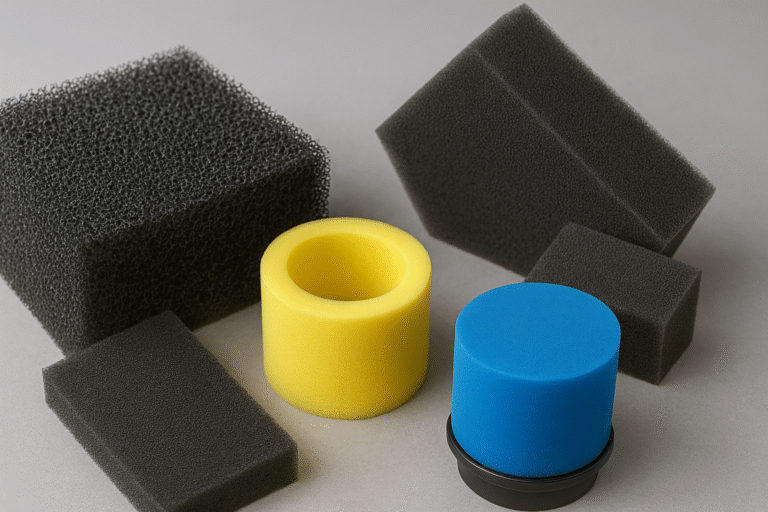

Filter foam is a type of porous foam specially designed to remove dust, debris, and other particles from air while allowing airflow to continue smoothly. Unlike solid materials, filter foam has an open-cell structure that makes it perfect for capturing contaminants without blocking the passage of air.

One common form is reticulated polyurethane foam, which is made by removing cell membranes to leave a 3D network of interconnected strands. This design creates high porosity, meaning air can pass freely while particles get trapped efficiently.

Filter foam comes in different types, densities, and formats — like filter foam sheets or custom-cut shapes — so it can fit everything from small HVAC systems to automotive air filters and industrial equipment. Its versatility makes it a key component in maintaining cleaner air in a wide range of settings.

Types of Foam Used in Air Filters

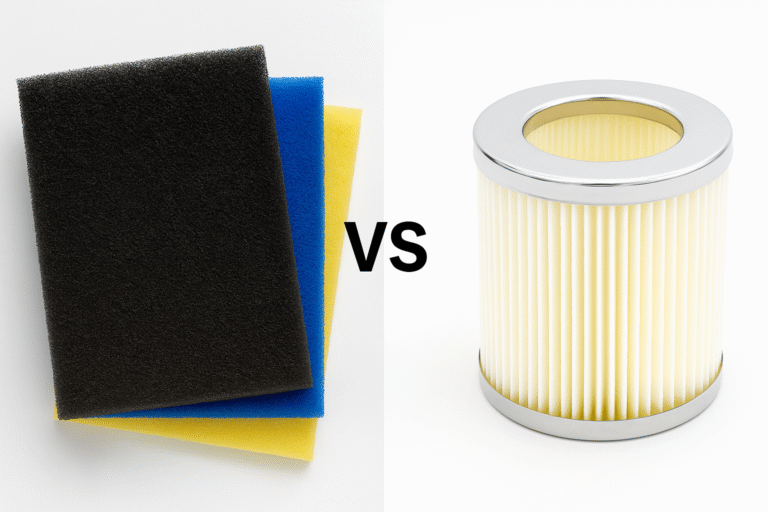

Air filters rely on different types of foam depending on the application and environment. The two most common types are polyester filter foam and polyether filter foam.

- Polyester Filter Foam: This foam is renowned for its durability and ability to withstand chemicals. It performs well in HVAC systems, automotive filters, and industrial settings where longevity is crucial. Regular use won’t cause it to lose its effectiveness or shape.

- Polyether Filter Foam: This kind is perfect for damp or humid environments because it is extremely resistant to moisture and hydrolysis. Applications such as air filters for kitchens, bathrooms, and outdoor spaces frequently use it. Whether for household use, automobiles, or industrial equipment, selecting the proper foam guarantees that your filters will last longer, maintain airflow, and function efficiently.

Features and Benefits of High-Quality Filter Foam

High-quality air filter foam offers more than just particle trapping — it improves efficiency, longevity, and overall performance of filters. Here’s what makes it stand out:

- High Porosity and Airflow – Open-cell structure allows air to pass freely while capturing dust and debris effectively.

- Custom Pore Sizes – Foam can be made in different pore sizes (PPI), ensuring it works well for both fine and coarse filtration needs.

- Washable and Reusable – Durable foam can be cleaned and reused, reducing waste and maintenance costs.

- Moisture, Chemical, and Heat Resistance – Ideal for challenging environments without degrading or losing shape.

- Lightweight and Flexible – Easy to install in compact filter housings or custom shapes.

With these benefits, filter foam sheets and custom foam inserts provide reliable filtration for a wide range of applications, from cars to HVAC systems and industrial setups.

Applications of Filter Foam

Filter foam is used across a wide range of industries and everyday applications where clean air or liquid is essential. Some of the most common uses include:

- Automotive Air Filters – Engine intake and cabin filters rely on foam to trap dust, pollen, and other particles, improving air quality and engine efficiency. To explore more about the benefits, types, and applications of automotive air filter foam, check out our detailed blog here.

- HVAC Systems – Air conditioners, heaters, and ventilation units use foam to remove dust and allergens while maintaining smooth airflow.

- Medical Devices – Respirators, ventilators, and surgical air filters use high-quality foam to ensure clean, safe airflow.

- Aquariums & Ponds – Foam supports mechanical and biological filtration, keeping water clean and promoting healthy aquatic life.

- Industrial and Electronics Applications – Used in machinery, printers, and electronics for dust control and protection.

From homes and offices to cars and industrial equipment, air filter foam plays a crucial role in keeping environments cleaner, safer, and more efficient.

The Importance of Choosing the Right Foam

The quality of air filter foam can have a significant impact on performance, as not all foam is made equal. Poor foam filtration and more frequent replacements can result from its propensity to tear, deform, or ineffectively capture particles.

Conversely, high-quality foam provides effective particle capture, steady airflow, and durability. Heat-, moisture-, and chemical-resistant foam lasts longer and works consistently even in harsh conditions.

Purchases of high-quality filter foam sheets guarantee that your air filters, whether in automobiles, HVAC systems, medical equipment, or industrial settings, will continue to function efficiently, require less maintenance, and produce cleaner air. Better foam simply translates into better filtration and more durable equipment.

Clean Air Starts with the Right Foam

Choosing the right filter foam is essential for efficient filtration, durability, and optimal airflow. From polyester filter foam to polyether foam, selecting high-quality materials ensures your air filters perform reliably across automotive, industrial, medical, and home applications.

At Kare Foam, we specialize in custom-engineered air filter foam and filter foam sheets designed to meet the exact needs of every application. Our advanced reticulation technology, ISO-certified facilities, and decades of manufacturing experience enable us to provide foams that are reusable, long-lasting, and incredibly effective.

Because of our adaptable, scalable, and high-performance solutions, we are a reliable partner for businesses in India and abroad.

Kare Foam offers reliable quality, prompt delivery, and knowledgeable technical support for any type of foam, including industrial setups, medical devices, automotive filters, and HVAC systems.

Contact us today to explore tailored foam solutions that keep your filters performing at their best.